In this episode, we'll learn how to drive meaningful learning outcomes in blue-collar and industrial settings using human-centered design, peer-led training, and clear performance metrics.

Meet our Guest

Thaddeus is the Director of Training at Phoenix Global, a steel mill services company. He is developing the Phoenix Training Center and conducting companywide needs assessments to improve employee performance and safety.

He has worked in training and development roles with sales and technical teams across industries, including the Sales Enablement & Training Team at U. S. Steel and the Global Education and Training Team at A-dec, a global leader in the manufacture of dental equipment. In these roles, he has facilitated sales and technical training on four continents, launched multiple digital training and coaching platforms, and created and facilitated live, virtual, and eLearning courses and curriculum to improve employee performance.

As a learning and development professional, Thad strives to equip professionals with the knowledge and skills they need to excel in their careers. Thad previously taught high-school and college-age learners and he holds a master’s degree from Portland State University.

From Paper to Platform: How to Digitize Field Learning

Background context: When COVID hit, Thaddeus Tsohantaridis was managing global training at a dental equipment manufacturer. Overnight, hands-on, in-person learning had to go remote. And then he joined U.S. Steel, where the challenge wasn’t remote work—it was any digital adoption.

Now at Phoenix Global, he’s helping heavy equipment operators trade in clipboards for tablets, and welding decades of institutional knowledge into flexible, accessible digital workflows. His story is a blueprint for field-first enablement done right.

Key Insight #1: You Can't Just Zoom the Classroom

Early COVID efforts to replicate six-hour trainings on Teams fell flat. Learners were exhausted, instructors frustrated. Thaddeus pivoted quickly.

They installed cameras in physical training spaces, launched pre-session surveys to tailor content, and leaned into scenario-based, self-paced learning. Engagement shot up. So did learner retention.

🎤 "We realized we had to stop trying to replicate classroom learning online. Instead, we focused on pre-work, video content, and asynchronous simulations."— Thaddeus Tsohantaridis

Key Insight #2: Surface What's Already Known

At U.S. Steel, the training team didn’t need to reinvent the wheel—they needed to find the wheels.

By launching a searchable, centralized sales enablement platform, Thaddeus turned tribal knowledge into team knowledge. The impact? Faster onboarding, fewer support calls, and higher productivity.

🎤 "There was so much institutional knowledge. The problem wasn't lack of resources, it was lack of access."— Thaddeus Tsohantaridis

Key Insight #3: Field-First Starts with Frustration

Whether it's a steelworker or a dental tech, no one likes wasting time. Thaddeus frames every change initiative around one question:

🎤 "What’s the pain point?""If you're here and you don't want to be, let's at least make it worth your time. Can you do something you couldn't do before? That's success."— Thaddeus Tsohantaridis

He applied that lens to ERP rollouts, maintenance workflows, and digital inspections—always leading with the operator's lived experience.

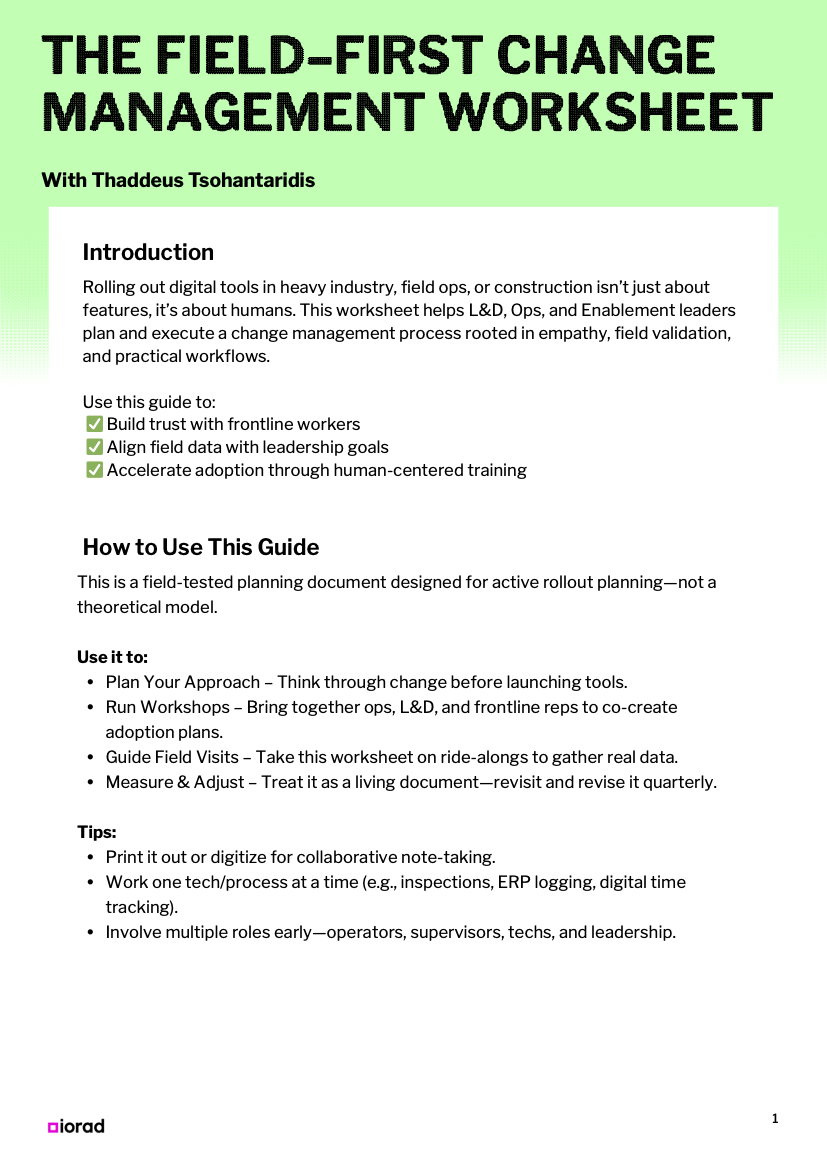

Free Adoption Template: Field-First Change Management Worksheet

The Problem: Field teams resist change because new tools often ignore real workflow pain points.

The Solution: Use this 5-step worksheet to guide your next rollout with the operator’s voice at the center.

- Identify the Workflow: What's changing? (e.g. inspections, parts tracking)

- Interview field users: What slows them down today?

- Map the gaps: Where will new tech help—or hurt—their process?

- Co-create a process: Build a "minimum lovable process" together.

- Design training to fit: Focus training on the end goal, not the tool.

Why this Works: Your primary job might be turning a wrench. But if we want good data and repeatable outcomes, we need to change how that gets recorded.

Field-First Change Management

Plan and execute change management processes rooted in empathy, field validation, and practical workflows.

Download